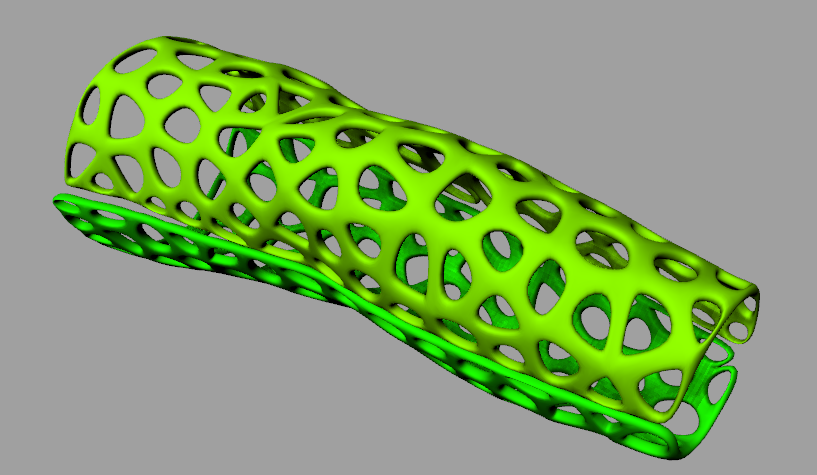

Traditionally, casts for broken bones are made from heavy, solid, non-breathable plaster. This can create discomfort and skin problems for the patient during the healing process, like itchiness, rashes and skin infections. Custom 3D printed casts made with a breathable, voronoi pattern are a potential DIY solution. This method is obviously not medically approved (as yet) and shouldn’t be used in place of seeing your doctor. However, if you normally wear a wrist split/other brace for injury you could create your own custom version of this with approval from your occupational therapist or specialist.

While this is a great potential solution, 3D modelling and 3D printing a custom cast or brace is time consuming. A standard 3D print of a wrist cast takes about 3 hours to print on a 3D printer, where plaster tends to take about half an hour to fit to a patient and is very cost effective. This method is a DIY solution for experimentation only. I’ve previously blogged on how to create Wrist Braces using Meshmixer, this method is more complex but has a better result and a better fit.

To make one of these, you’ll need a 3D scanner and a copy of Meshmixer and Rhino 3D software, with Grasshopper, the algorithmic modeling plugin installed.

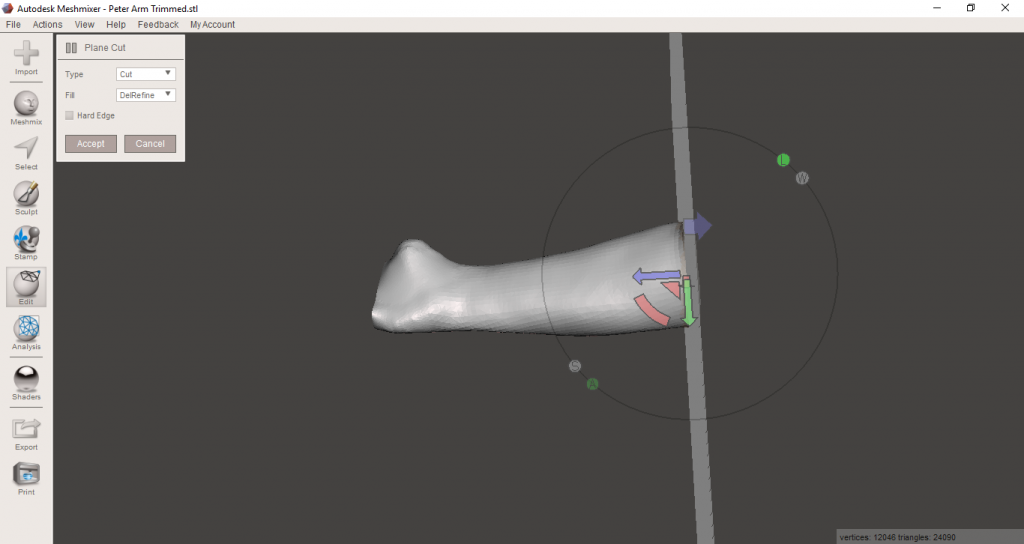

First, you’ll need to take a good scan of the area you’d like to make a brace for. I recommend asking ‘patient’ to hold their arm out and resting the fingertips on something to stop the arm from involuntarily shaking. Import the 3D scan into Meshmixer, and use the Plane Cut function to cut away the areas you do not want, i.e. the fingers, thumb and arm. You may also want to do some cleaning with the brush tools depending on the quality of your 3D scanner.

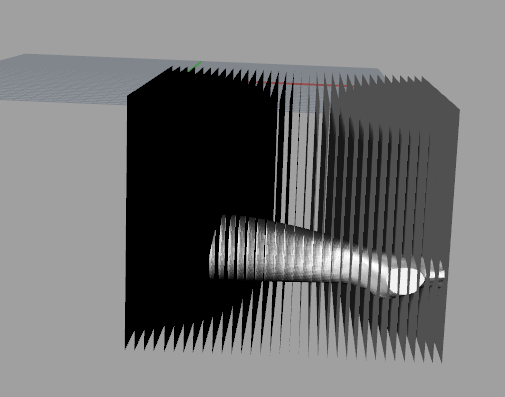

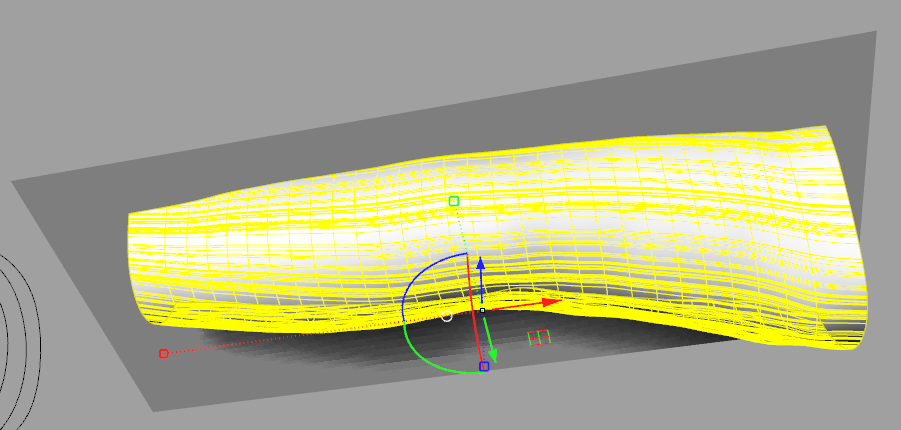

Next, import your trimmed arm model into Rhino 3D. Use the function MeshtoNURBS to convert the .stl into a polysurface. Create an array of roughly spaced surface planes to fit the length of your scanned model, like the images below.

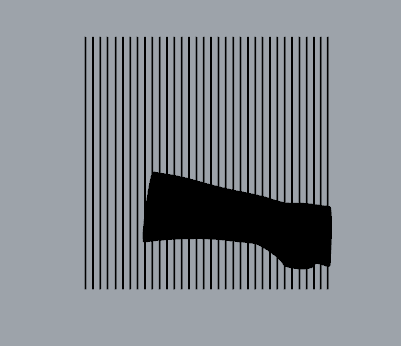

Next, use the function IntersectTwoSets and highlight first your surface planes, and then the arm model. You will create a series of ‘plane cut’ style curves like the image below.

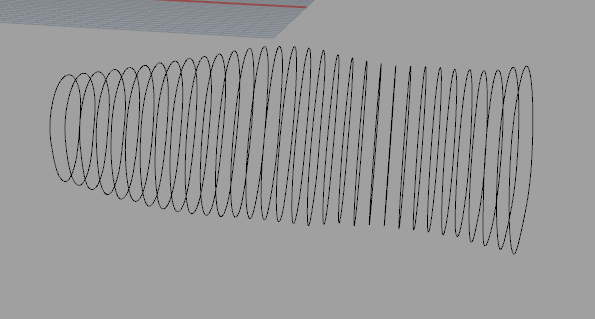

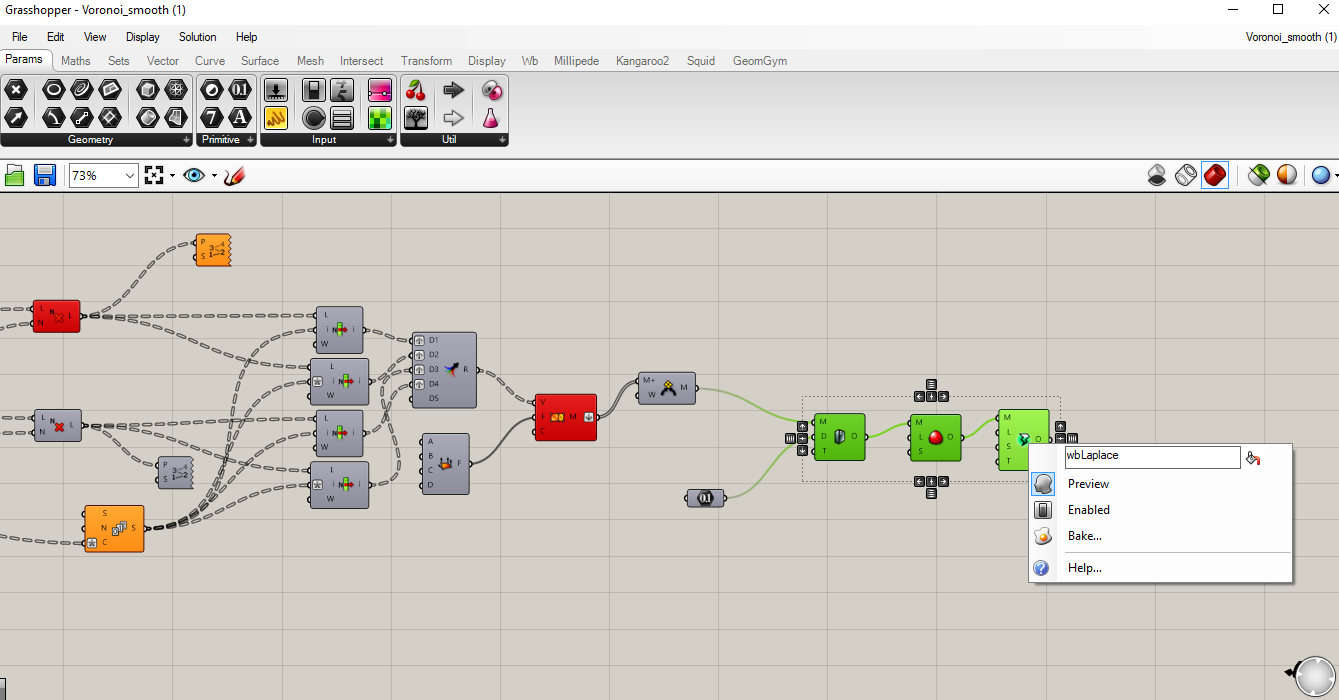

Sometimes these curves will come out a bit irregular. Use the function _Rebuild on the curves to fix this. Next, use the Loft function to create a new surface using the arm curves. You’ll need to select the curves in order for this to work correctly.

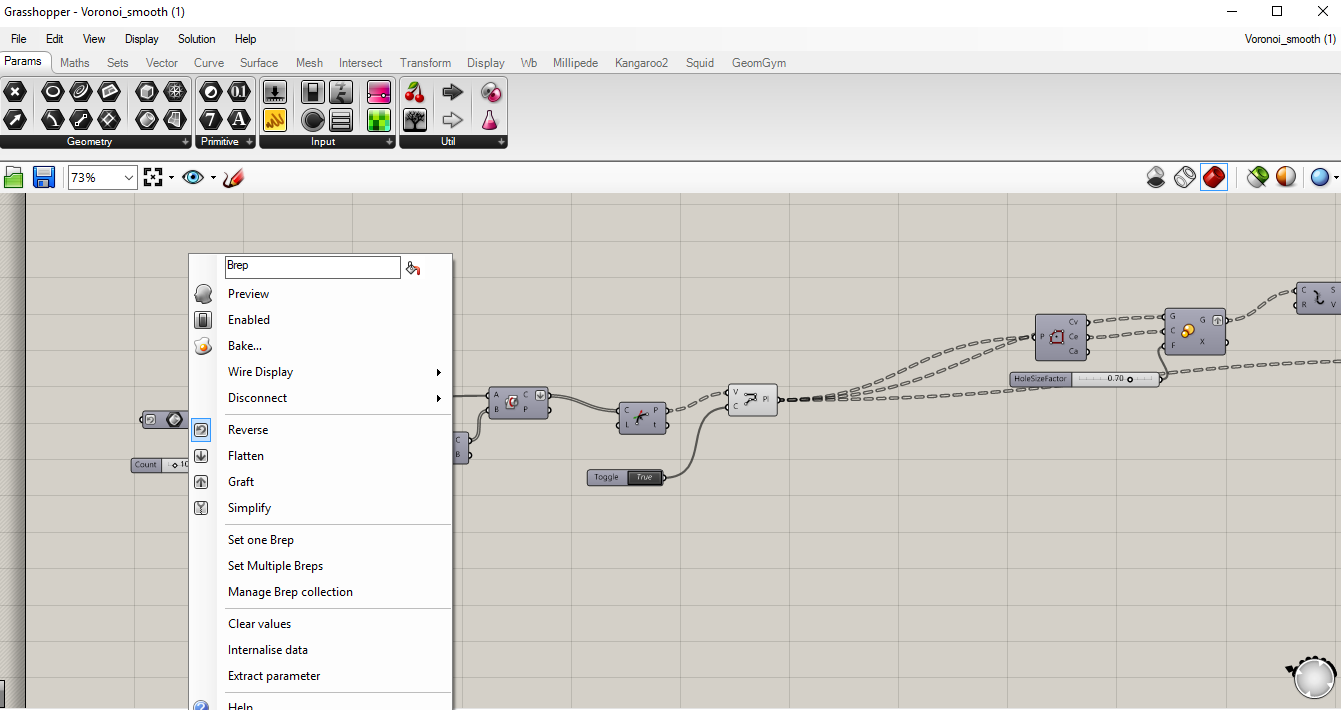

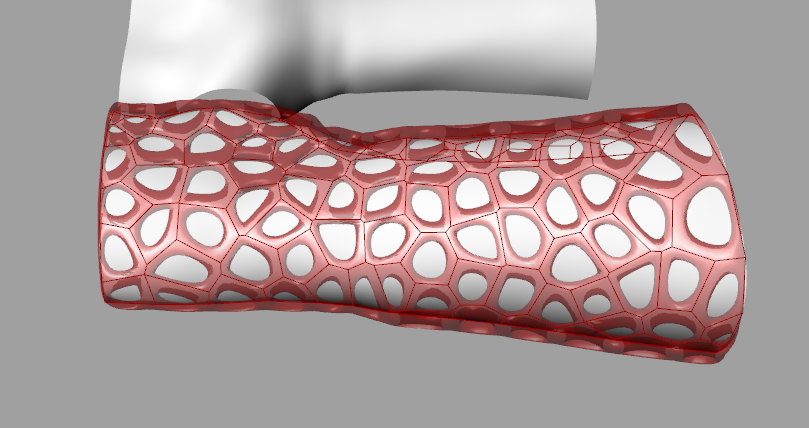

Next, use the function OffsetSurf to create a surface 2mm above the existing surface. This will make sure the brace will sit nicely on top of the skin. You can also cut the brace in half by using the Boolean split tool. Launch Grasshopper for the next step. You’ll need to download this Voronoi algorithm and open it in Grasshopper.

Right click the first Brep input component of the algorithm and select Set one Brep and click on the first half of the brace when prompted. This will now map a voronoi pattern to the offset arm scan. You can go through the algorithm and tweak different aspects, including the hole size and more.

After you’re happy with the outcome, highlight the last section of the algorithm, right click and choose Bake.

Repeat the process on the other half of the brace. You now have a voronoi brace!

You should be able to print this standing upright without any supports. You can use ribbon and beads to act as a hinge, or 3D model on a hinge of your own design. Xkelet has some great designs for inspiration. Enjoy!

Comments 2

Hi there,

My mum is permenantly disabled in her thumb due to an accident at work and misdiagnosis from the NHS. They thought it was fractured at first so casted it up but turned out to be ligament damage so being in the cast actually caused permenant and painful disability in most of her hand. She now has to wair a gauntlet with extra thumb support daily but these gauntlets aren’t breathable and dont support her thumb enough. She has asked me to try and 3D print her a breathable cast and after endless 3D modeling attempts and 3D scanning from my phone of her casts i just cant seem to get a good result. I would be so so happy if there is any way that i could work colaboratively with someone to develop a 3D model cast for her so that i can print it out for her. I would be happily willing to pay towards the time spent on this, if this would be possible. Please do let me know if you can help in any way.

Kind regards

Max Chapman

Author

Hi Max, Happy to see if I can help you out with this somehow. It sounds like you just need to invest in getting a good, high quality 3D scan to start. If you’re around the Brisbane area, I recommend using Ditto Labs: https://www.dittolabs.com.au/. Feel free to send me an email at [email protected] if you’d like to chat.

Cheers,

Steph